User Guide

Weibull distribution

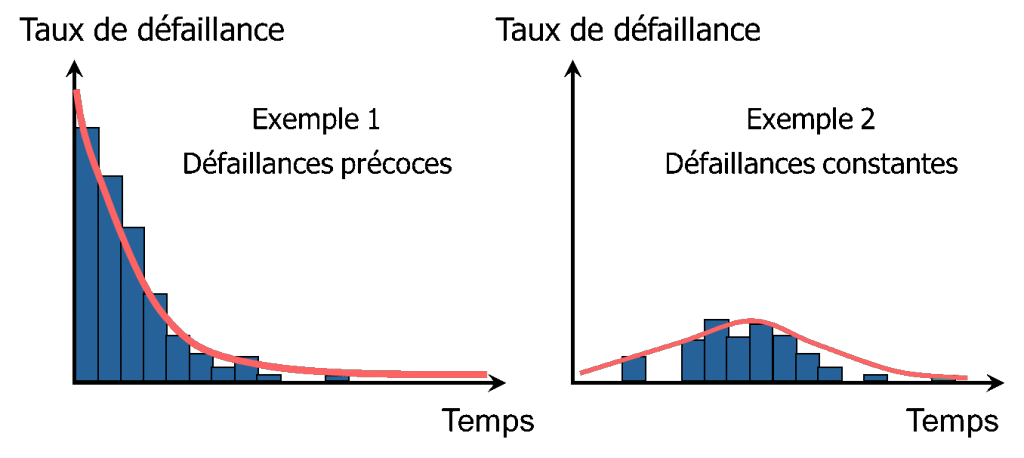

In order to create a model of the failure distribution of a product, it is necessary to be able to model multiple types of failure:

Therefore, considerable shape flexibility is necessary. The distribution primarily used for this is the Weibull distribution because it allows for a greater shape variability.

Because of its flexibility, the Weibull distribution makes the modelling of the behaviour of numerous types of failure possible, such as

- Components' resistance to rupture or the effort required to wear out metals.

- The failure time of an electronic component.

- The failure time for articles used outdoors such as pneumatic automobiles.

- Systems that fail when the weakest component in the system contains a defect. The Weibull distribution also supports the modelling of the behaviour of different lifespan situations for one component. The function of the Weibull distribution is as follows:

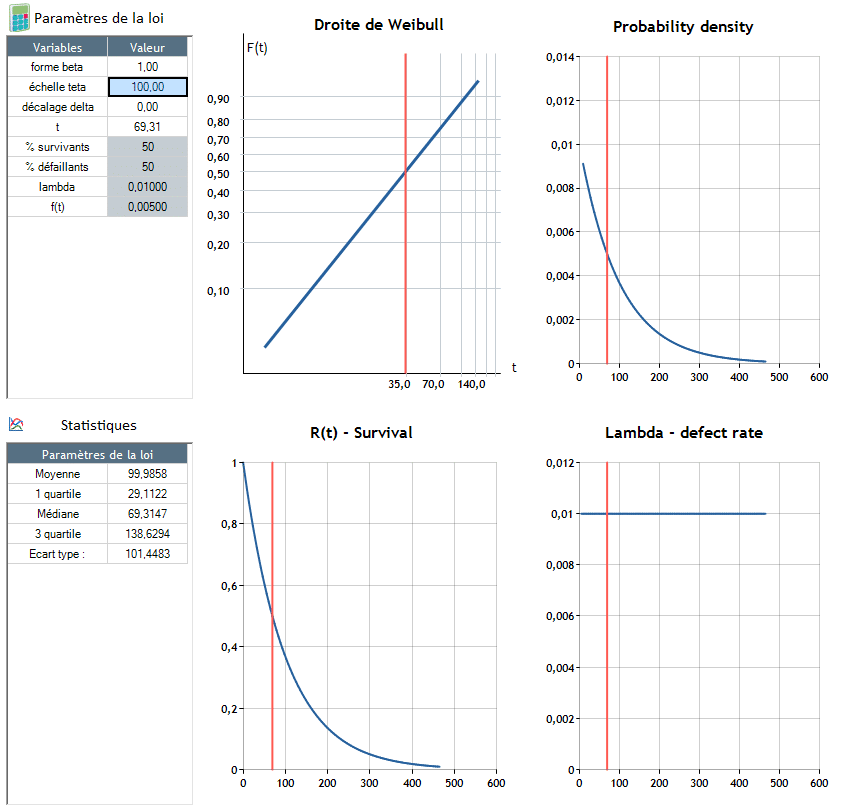

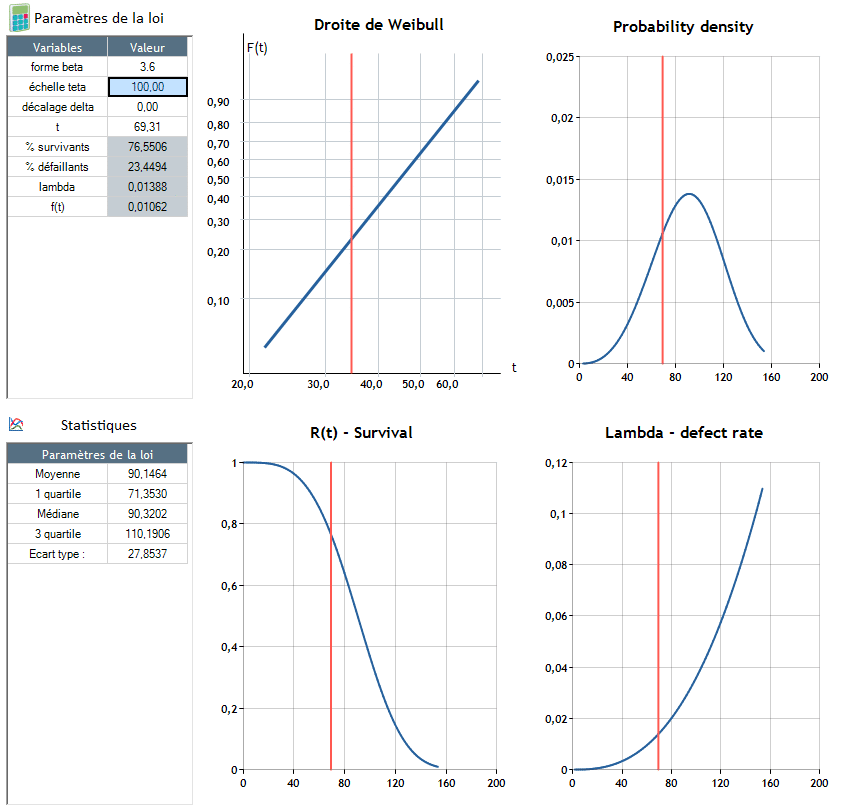

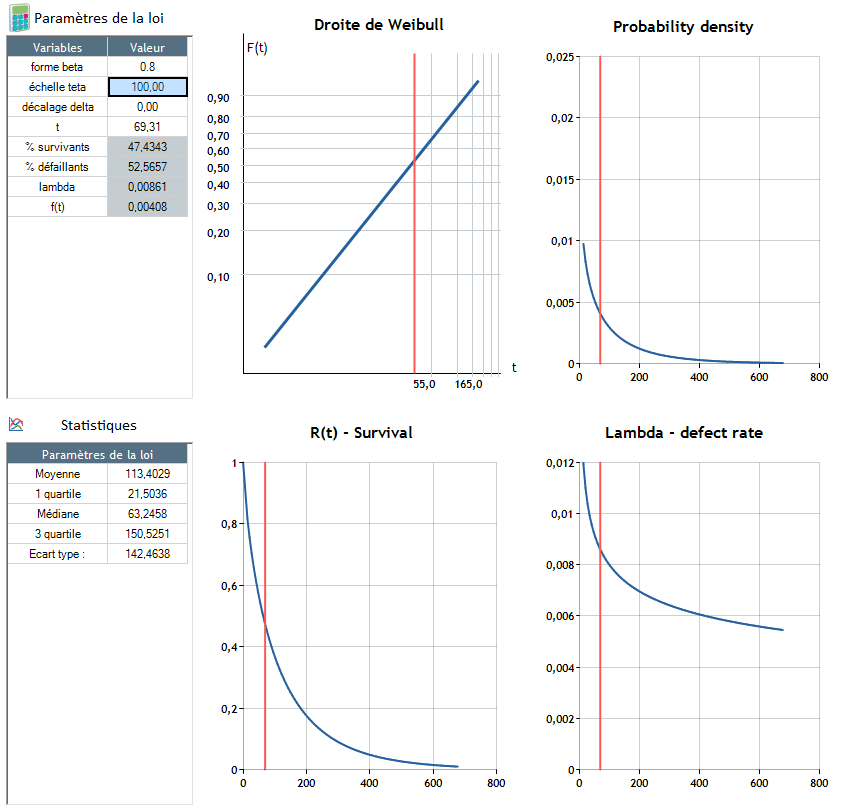

It is composed of 3 parameters:

- β - shape parameter

- θ - scale parameter

- δ - delay parameter

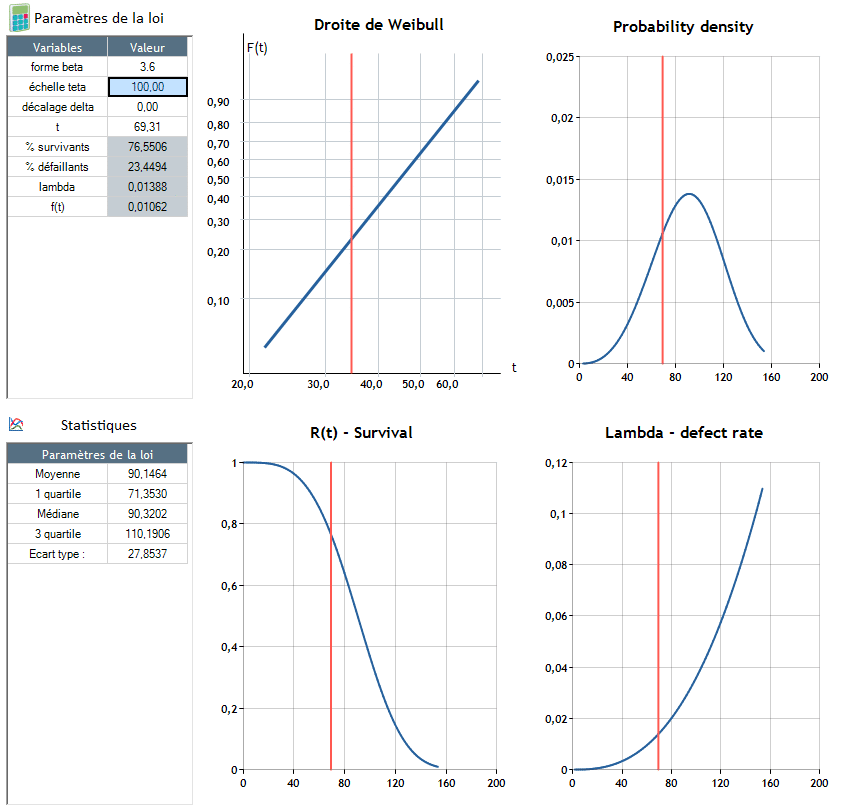

β, shape parameter :

It makes adaptation of the distribution's shape possible to place it as close as possible to the observed failure rate:

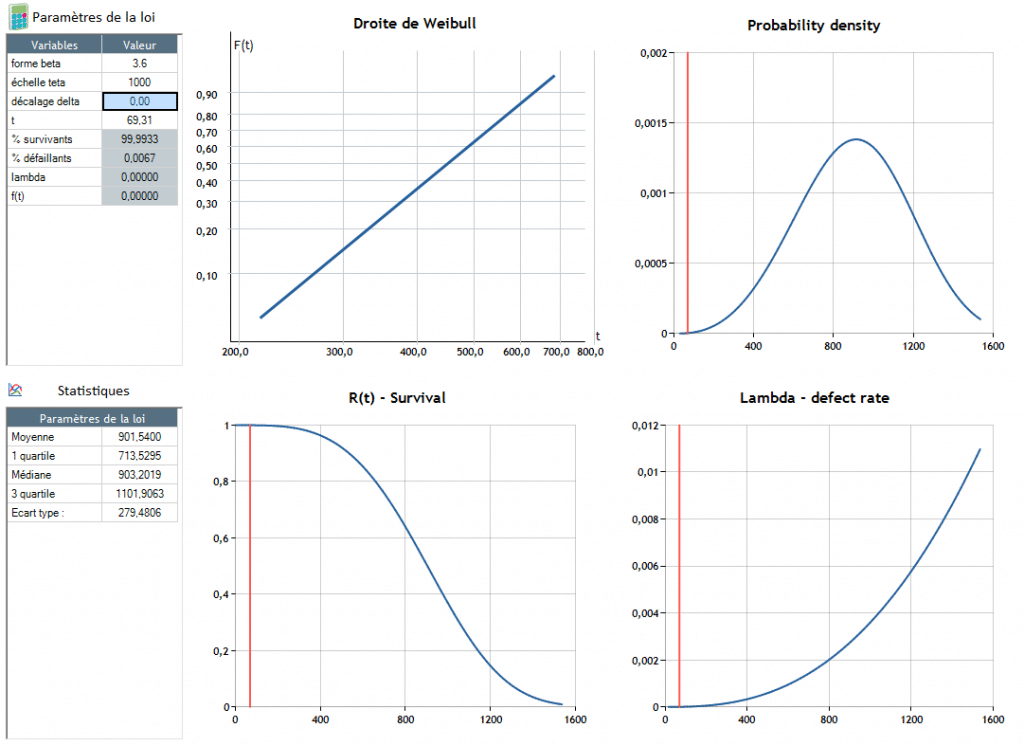

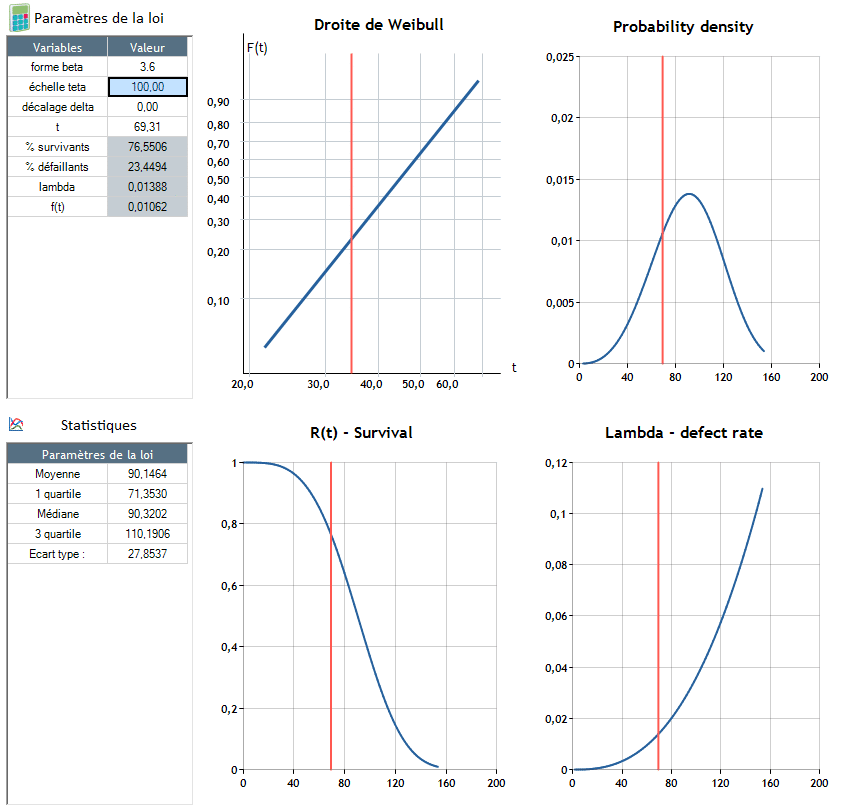

θ, scale parameter :

The θ parameter makes it possible to adjust the scale of the distribution law to the scale of the observed problem, for example:

Failure appears around t = 90.4

Failure appears around t = 904

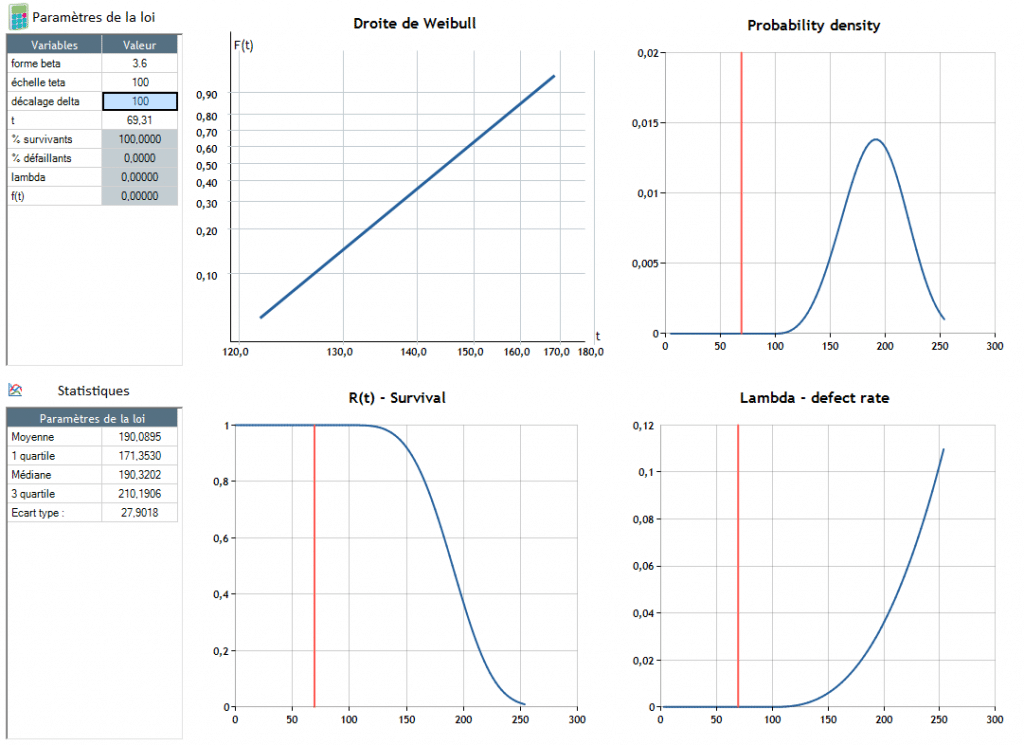

δ, delay parameter:

The δ parameter makes it possible to move the distribution law by one parameter δ

Failure appears around t = 90.4

Failure appears around t = 190.4